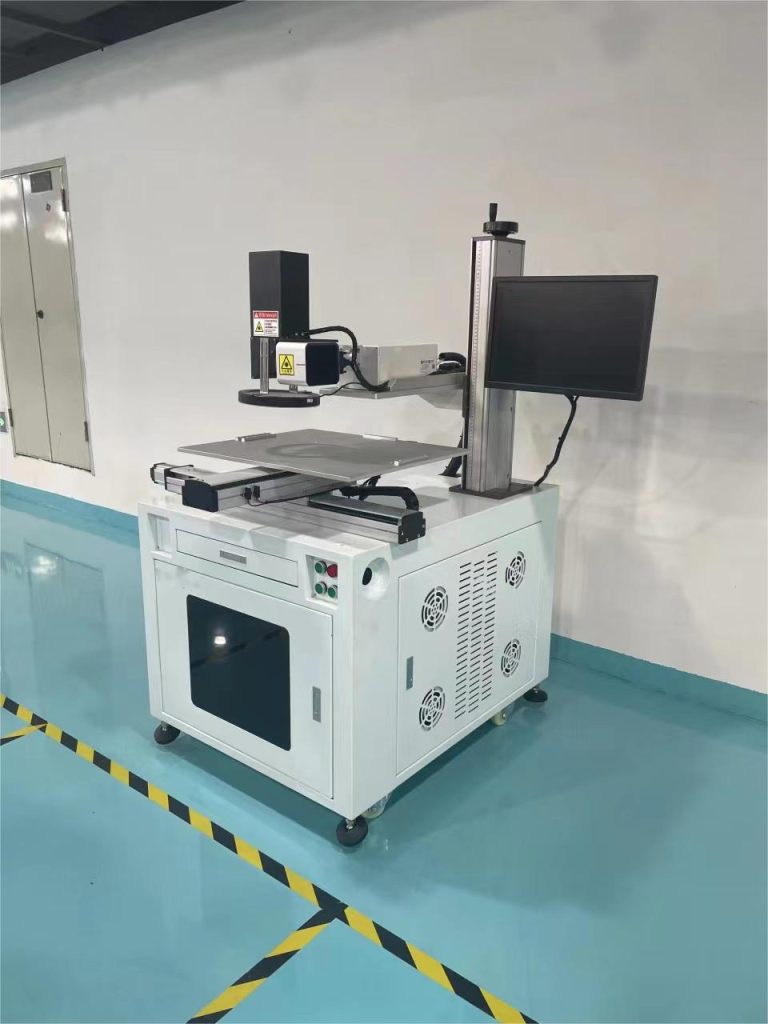

PCB Laser Marking Machine

Machine Parameters:

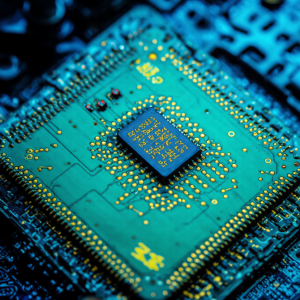

The PCB laser marking machine’s compatibility with various PCB surface types, combined with its high-precision marking capabilities, makes it an indispensable tool in modern PCB manufacturing.

The ability to generate and mark QR codes is a significant feature of modern PCB laser marking machines. This allows for efficient traceability and identification of circuit boards throughout the production process.

In addition to QR codes, these machines can also implement barcodes for inventory tracking and management. This feature is particularly useful in high-volume manufacturing environments.

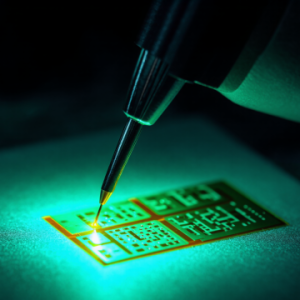

The precision of PCB laser marking machines enables the marking of characters and patterns with high accuracy. This is crucial for applications requiring detailed identification or aesthetic designs.

With 10-50 µm accuracy, these machines can handle complex designs and intricate patterns, making them ideal for a wide range of industrial applications, including those requiring copper surface laser marking. The integration of such technology with MES systems further enhances production efficiency.

By supporting various marking types, including QR codes and barcodes, and offering high precision, PCB laser marking machines play a vital role in modern electronics manufacturing, facilitating MES-integrated laser marking processes.

The latest generation of PCB laser marking machines boasts an array of sophisticated features that significantly enhance their functionality and efficiency in the PCB industry.

One of the standout features of modern PCB laser marking machines is their ability to integrate with Manufacturing Execution Systems (MES). This integration enables automated data retrieval, streamlining the marking process and reducing manual errors. By connecting directly to the MES, the laser marking machine can access critical product information, such as part numbers, serial numbers, and production dates, ensuring accurate and consistent marking.

Zero Consumables Technology

Parameter | Specification |

|---|---|

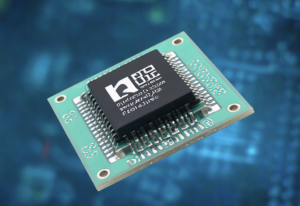

Model | K-4500AT |

Laser Types | CO₂, Fiber, MOPA, UV, Green (Selectable) |

Laser Wavelength | 10640nm (CO₂), 355nm (UV), 532nm (Green), 1064nm (Fiber & MOPA) |

Laser Power | 5-15W (CO₂), 3-5W (UV), 5-10W (Green), 20-30W (Fiber & MOPA) |

Marking Accuracy | ±0.02mm repeat precision |

PCB Capacity | Max 450×450mm |

Material Thickness | 0.5-5mm |

Marking Content | Text, 1D/2D barcodes, graphics |

Positioning System | CCD/Mark-point alignment |

Data Interface | MES integration & auto generation |

Cooling System | Air/Water cooling |

Power Requirements | AC220V/7A/50Hz |

Throughput Speed | 0-3000mm/s conveyor speed |

Double-side Marking | Built-in flipping mechanism |

Minimum Marking Size | 1.5×1.5mm |

Software | Simplified/Traditional Chinese/English interface |

Compliance | Class 4 laser safety |

Benefits of PCB Laser Making Machine

Fully-automatic precision marking capability

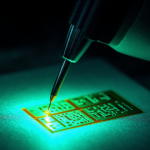

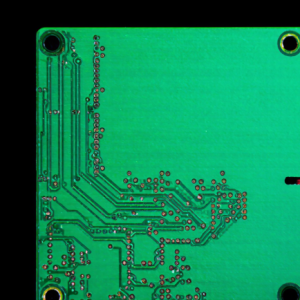

Precision automatic marking on white oil, green oil, black oil and other types of ink surfaces and copper surfaces, supporting the automatic generation and marking of 2D codes, barcodes, characters and patterns.

Integration of production information technology

Automatically obtain the batch, date and other specified information from the MES system, and directly generate two-dimensional code for marking and engraving, to achieve product information control in the production process.

Powerful software

Equipped with special control software, it supports automated data docking and real-time monitoring to enhance operational efficiency.

Application Demonstration

Key Features:

- MES Integration: Automatically retrieves batch/date data from MES, generates QR codes, and marks them directly on PCBs for real-time production tracking.

- Zero Consumables: Eliminates ink/chemical usage, reducing operational costs and environmental impact compared to traditional spray printing.

- Multi-Laser Compatibility: Configurable with fiber (1064nm/20-30W), UV (355nm/3-5W), CO₂ (10640nm/5-30W), or green lasers (532nm/5-10W) to meet diverse material requirements

- Industrial-Grade Durability: Class 4 laser safety standards with air/water cooling options ensure stable performance in high-volume PCB production environments

Ideal for PCB manufacturers needing permanent, tamper-proof markings for compliance, anti-counterfeiting, and supply chain management.