fiber laser marking machine

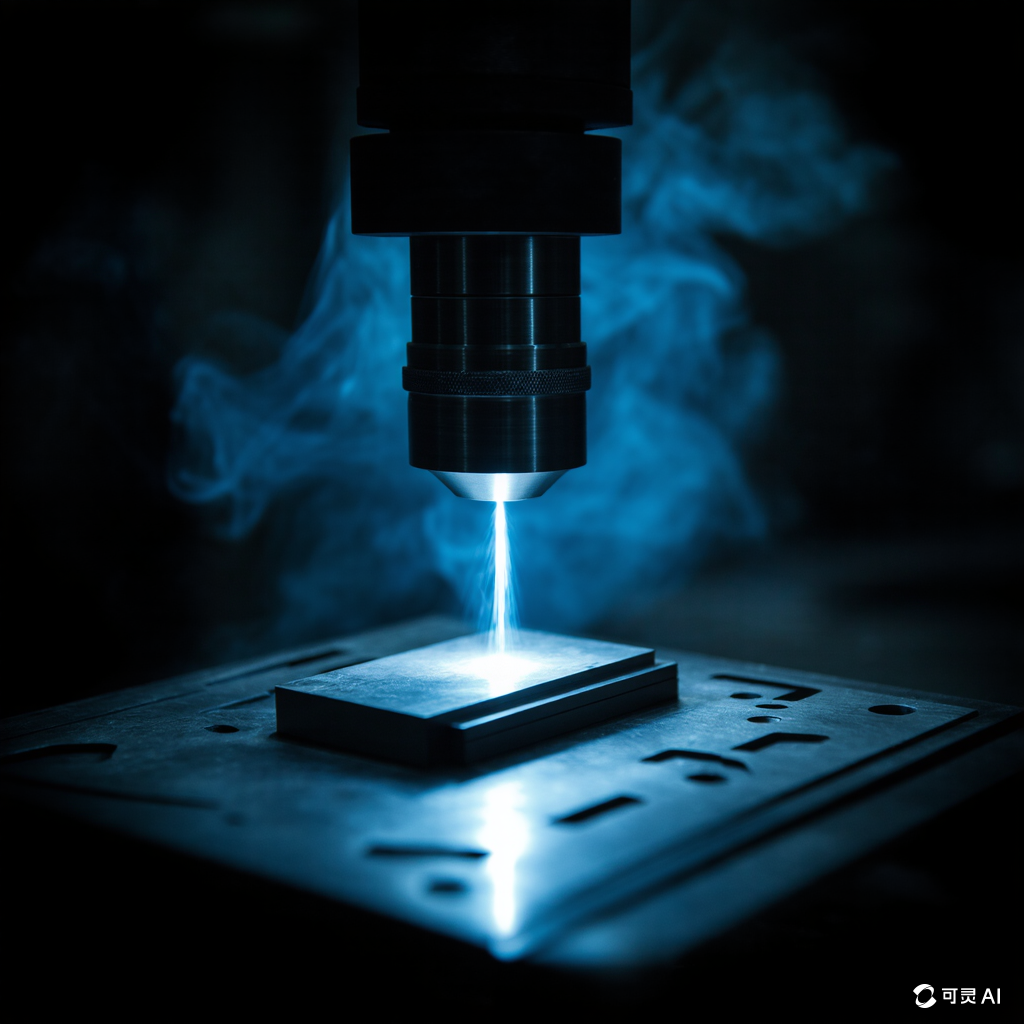

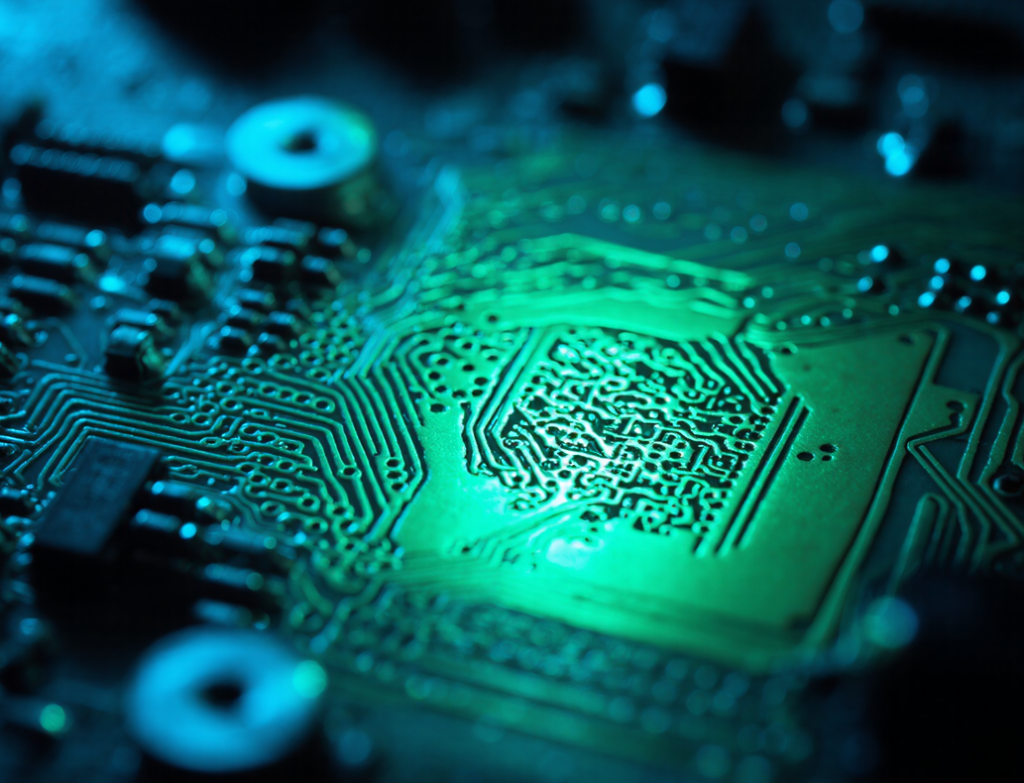

High-performance fiber laser marking systems are transforming industrial manufacturing. They operate at a 1064nm wavelength, making them ideal for marking metals like stainless steel and aluminum, as well as plastics and coated surfaces. These high-precision marking systems come with power options typically ranging from 20W to 50W for standard marking, with higher powers up to 100W available for specialized applications like deep engraving. They can mark at speeds typically ranging from 1000mm/s to 7000mm/s, depending on material, power, and marking complexity, making them suitable for large-scale industrial jobs. The technology ensures consistent, high-quality marks, aiding in product tracking and authenticity.

Industrial laser marking has evolved significantly over the years, driven by technological advancements. Initially, industrial laser marking relied on CO2 lasers, which struggled to mark metals effectively. The introduction of fiber laser technology marked a significant leap forward, enabling faster and more precise metal marking. As laser part marking grew, the demand for improved machines spurred further innovations. Today, machines deliver superior speed and precision compared to their predecessors. The journey of industrial laser marking technology continues, with scientists and engineers working to enhance speed, accuracy, and material compatibility.

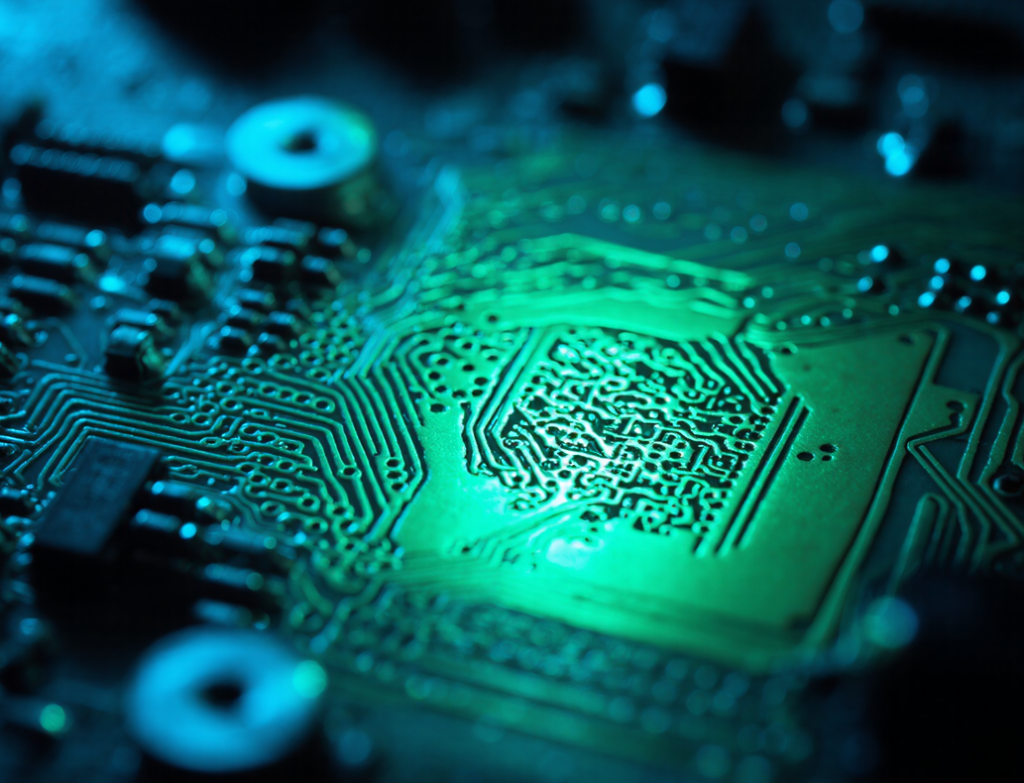

Fiber laser marking machines stand out for their high precision laser marking capabilities. They leverage fiber laser technology to produce precise, high-quality marks. These laser etching machines can mark a wide range of materials, including metals and plastics. Key features that make them exceptional include:

- High precision and accuracy in marking

- Durability and resistance to wear and tear

- Ability to mark a wide range of materials

- High-speed marking capabilities

- Low maintenance requirements

These machines excel at marking stainless steel and aluminum, producing detailed, permanent marks without damaging the material. This is critical for industries requiring traceability and product identification.

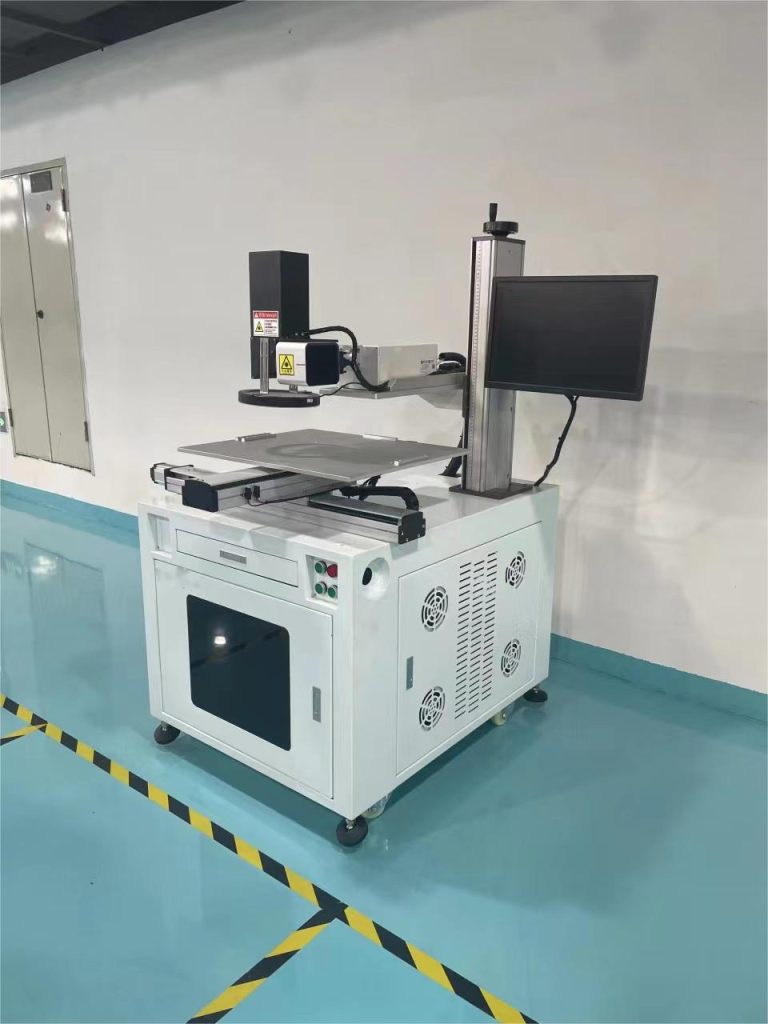

Machine Parameters:

| Category | Parameter | Specifications |

|---|---|---|

| Core Parameters | Model Series | Y-F20V / Y-F30V / Y-F50V / Y-F80V |

| Laser Type | Fiber Laser | |

| Wavelength | 1064 nm | |

| Laser Power | 20W / 30W / 50W / 80W (Selectable per model) | |

| Performance | Marking Area | 30×30 mm ~ 300×300 mm (Optional configurations available) |

| Repetition Precision | ±0.03 mm (Plane) | |

| Vision Positioning | Template positioning system | |

| Hardware | Camera Resolution | 6MP / 10MP / 12MP / 20MP (Configurable per application) |

| Lens Options | 8 mm / 12 mm / 16 mm / 25 mm | |

| Light Source | Combination strip light / Circular light / Backlight | |

| Light Controller | Digital sequence control & Manual override | |

| Marking Card | JCZ PCIE | |

| Material Handling | Feeding System | Vibration disk / XY Module / Assembly line / Tape weaving machine / Customizable |

| Motion Control | Motion card / Servo motor / Stepper motor | |

| Environment | Operating Temperature | 10°C to 35°C |

| Humidity Range | 5% to 75% (Non-condensing) | |

| Software & Power | Control Software | VIPin Laser Marking System |

| Power Supply | 220V AC, 50Hz, 10A circuit breaker (Stable voltage required) | |

| Physical | Weight | ~80 kg |

| Dimensions (L×W×H) | 800 × 1000 × 1450 mm |

Benefits of The Desktop Laser Marking Machine

Cost-Efficient Laser Marking

The built-in fiber laser head is virtually maintenance-free and highly reliable. It consumes minimal energy and eliminates expenses for consumables, spare parts, or maintenance.

Effortless Laser Marking Like Printing

The preinstalled fiber laser marker software functions as a printer driver, seamlessly compatible with all graphics, CAD, and label printing programs. No need for importing or converting—simply hit print to start marking.

High-Speed Fiber Laser Marking

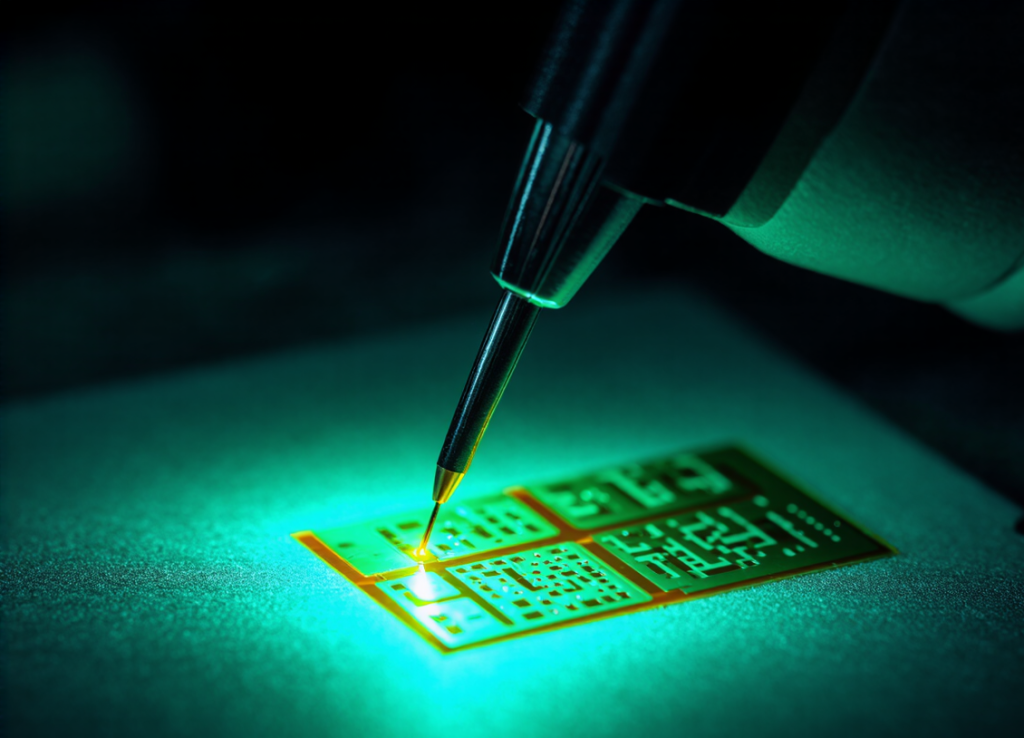

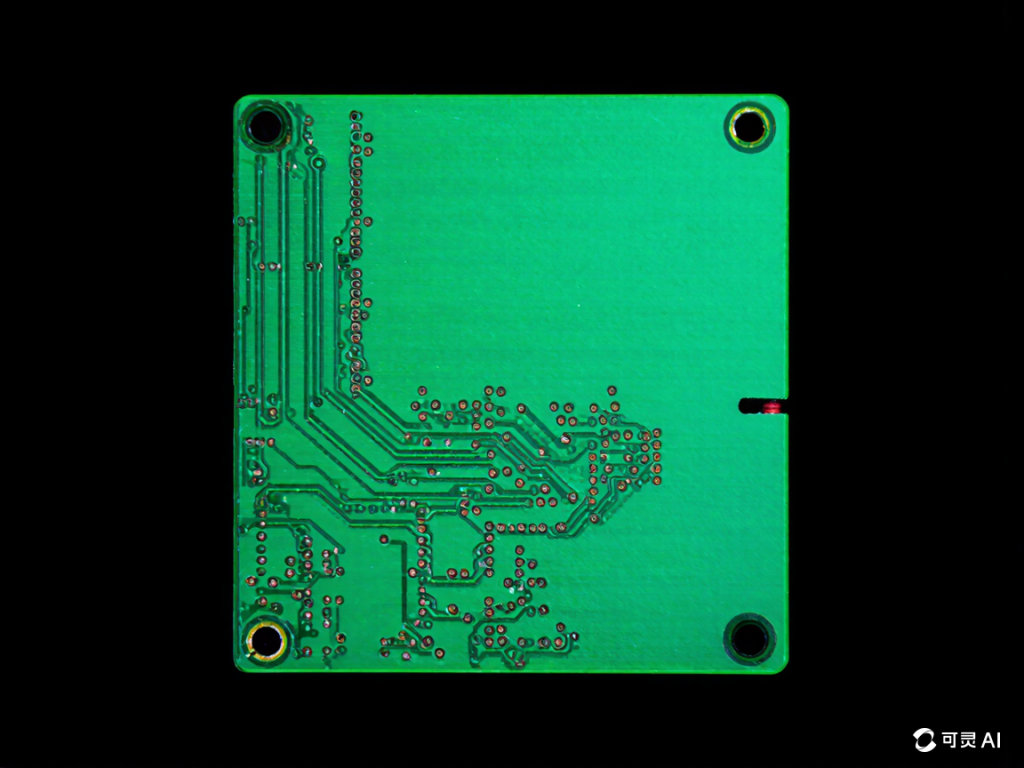

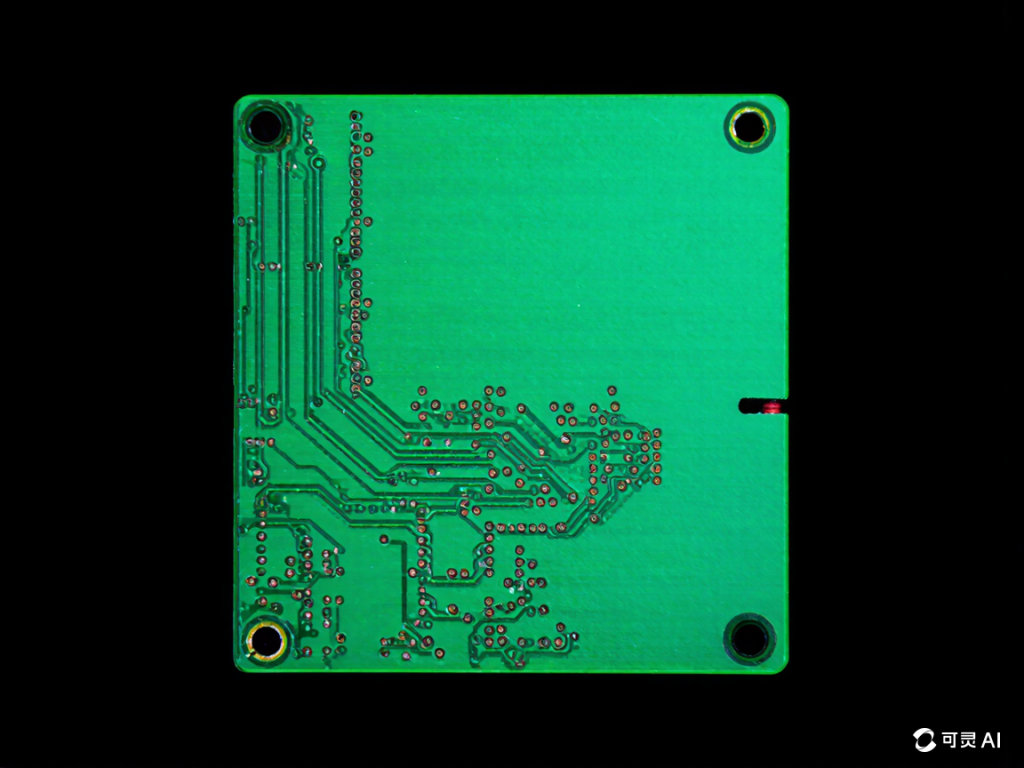

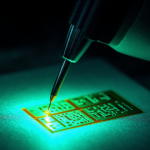

The fiber laser marker is designed for rapidly marking large batches of small- to medium-sized parts. It can engrave PCB circuit boards or metal dataplates in just seconds.

Application Demonstration